Typical weld lines are shown in Figure 3.10. These are prone to occur where the material flow separates around an obstruction.Where the material meets again, the material fronts have slightly cooled, and this prevents the two fronts joining together properly.

This can result in a plane of weakness, sometimes leading to mouldings breaking.

Meld lines occur where a moulding has more than one gate these can also result in a similar plane of weakness where the material flow fronts join.

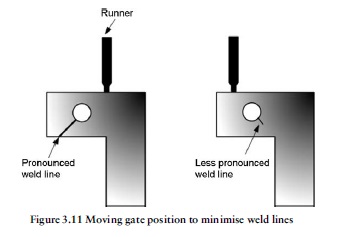

The choice of gate position is important in minimising the weld lines as shown in Figure 3.10. Wherever the material flow meets an obstruction weld lines are very likely to occur and the position of the gate should be carefully considered to minimise this effect at the mould design stage. In critical applications it may be worthwhile carrying out a flow analysis to optimise the size and position of the gate (see Figure 3.11).