The type of material being used will influence the choice of ejectors and the number of ejectors required.For example, with brittle materials like polystyrene, the part would

have to be supported a great deal more than would tough materials like Nylon. Brittle materials are easily prone to cracking or even breaking during ejection unless sufficient attention has been paid to this point.

On the other hand, it is often possible to get away with much less ejection support with the stronger self-lubricated materials, as they are stiffer and tough enough to transmit the ejection force to all parts of the moulding. Some soft materials can lead to the material compressing and ‘bellying out’ at the point of ejection, resulting in the moulding resisting being stripped from the core.

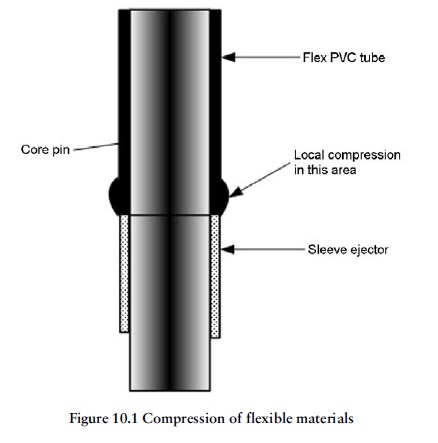

Flexible materials, like flexible PVC or certain grades of polyurethane, pose considerable ejection problems and require a lot of thought in designing the ejection system. Figure 10.1 shows a typical example. In this arrangement, the moulded, flexible PVC tube is extremely likely to buckle when ejection takes place. The reason is that the ejection force is not transmitted through the entire length of the tube and tends to concentrate at

the point of ejection. In fact it may not be possible to eject this component at all, because of this problem. In such cases, it may be necessary to use a stiffer grade of material before satisfactory ejection can take place.