For the part below , if the relationship between the gate hole and the concentricity tolerances is important then a two-plate tool might not be the best choice.This is because gating this part from the side might lead to differential shrinkage and warpage due to the unequal melt flow length. If this were important, a three-plate tool or hot runner tool would be preferred as the part could be gated at the top, providing more equal melt flow lengths.

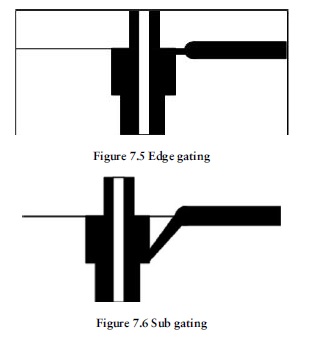

In our example, this is not the case and we may therefore gate the part on the edge of diameter Y at the split line as shown in Figure 7.5 or with a sub gate shown in Figure 7.6.

If we require millions of parts per year, sub gating is the obvious choice as the parts will be automatically de-gated.

-

Subscribe

Subscribed

Already have a WordPress.com account? Log in now.