We could eject the below part with pins, with a stripper plate orwith sleeve ejectors. It is always preferable to avoid pin gating if the options of stripping or sleeve ejection exist, for three reasons:

1. The ejection area of pins is smaller than in the other methods and we would achieve far greater ejection support with stripping or sleeve ejection. This eliminates the tendency of pins to hob or embed themselves in to the part.

2. For an eight-impression tool we would need 32 rather slender pins for ejection, which entails more toolmaking work and alignment.

3. The relatively slender pins may tend to deflect in the tool during ejection, causing premature wear and breakage.

This leaves the choice between stripper plate or sleeve ejection, so how do we choose between them? Basically the governing factor is the diameter of the part being stripped. Generally, smaller diameters should be sleeve-ejected and larger diameters stripped. The cut-off point should be around 30 mm diameter. This is around

the maximum comfortable size for toolmaking and for working with standard mould components.

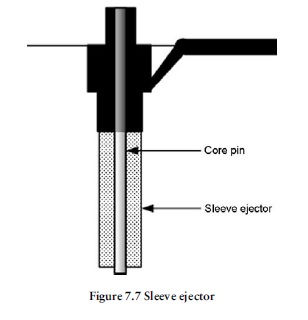

In this case the diameter of the base of the moulding is 15 mm and therefore we will opt for sleeve ejection (Figure 7.7).