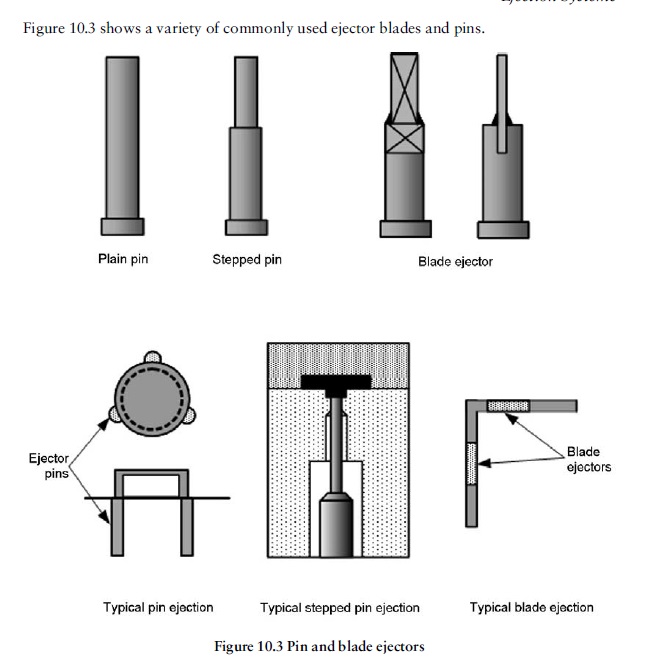

Ejector pins are the most common method of ejecting parts from the cavity.These should always be hardened for production tooling. Three variations are normally used:

- Nitrided pins. These are pins that have been heat-treated in a molten salt ferritic

bath or gas to introduce nitrogen into the surface of the pin. They have good wear

resistance and are used for all normal ejector pin applications. - Tuftrided pins. Tuftriding introduces nitrogen and extra carbon into the pin surface,

giving a harder surface and leaving a softer core. This has distinct advantages where

slender pins have to be used that may be subject to flexing during operation. - Through-hardened pins and blades. These are hardened in the same way as cavity

parts, using nickel–chrome steels. This technique is used for larger core pins and

pins that form the core of a sleeve ejector.

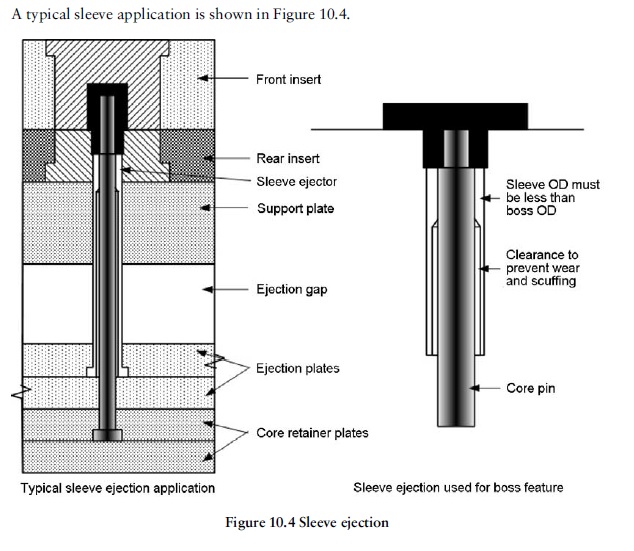

Sleeve Ejectors

Sleeve ejectors are used to eject on circular features such as circular pads, bosses or

recessed holes. Like ejector pins, sleeve ejector assemblies are available as standard

components in a wide variety of sizes. Nonstandard sleeves can be made by adapting

standard ones; failing this, they will have to be specially made.